Introduction

Choosing the right plastic crusher machine actually depends upon different factors such as application, knives sizes, cutting chamber, and much more. Based on the combination of all these details, you can decide what plastic recycling granulator will suit your needs. This blog highlights all those important characteristics to help you make a better decision regarding your plastic recycling granulator machine.

Factors To Consider While Choosing A Plastic Crusher Machine

- First of all, you need to consider the application factor of your plastic granulator machine. When you put any type of plastic in the cutting chamber, then the speed of its processing will always depend on the type of your given material.

When you feed any kind of soft material, the cutting speed will increase automatically, and hence the processing will also increase. Some examples of those soft materials are polyethylene and polypropylene.

On the other hand, when processing hard materials, the speed of granulating will always be lower than the soft material processing speed. These hard materials are also known as engineering materials. Some examples of engineering materials are PC, Nylon, ABS, and other such higher grade products.

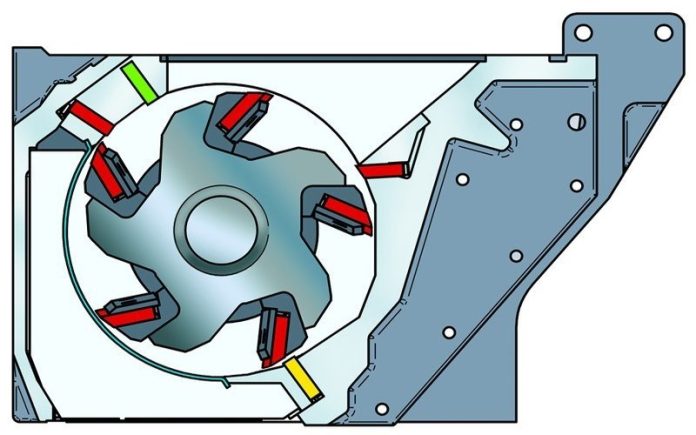

- The next factor to be considered is the cutting chamber as well as cutting knives. If you want some higher processing capabilities then you should make a combination of a larger cutting chamber, bed knives, and a longer rotor.

- Quality, as well as quantity of knives, also matter a lot when you are choosing the right plastic granulator or plastic crusher machine for your business.

- You can ask the manufacturer to customize the one according to your requirements. For this purpose, you have to discuss with the manufacturer the details and requirements of the final output that you want. Based on those details, a manufacturer will be able to manufacture the right plastic crusher machine for your business. When talking about knives, a common plastic granulator has 2-3 bed knives or stationary knives and 3-6 rotor knives. The overall speed of your plastic crusher machine depends upon factors such as the number of knives, granulator type, chamber size, and speed of the motor.

- Another factor to consider when choosing the right plastic crusher machine is the electric motor. It is the most important part of your plastic granulator. When choosing the perfect quality plastic granulator, make sure that your manufacturer doesn’t make use of a low-quality granulator. It is a common practice in Asia to use low-quality electric motors so that costs are saved.

- Lastly, the screen size will help you to control the size of the resulting regrinds. It is a Common fact that smaller grinds can result in slower speeds as compared to larger grinds. You have to make a suitable decision about screen size based on the screen hole size that may range accordingly.

Conclusion

You should keep in mind all the characteristics explained above when choosing the right plastic granulator for your business. You can make an excellent decision based on these factors even without consulting with someone expert. However, such large decisions always need careful planning that only an expert can do for you.