Steel Pipe Weight Guide: Manual Formula Vs. Calculator Accuracy

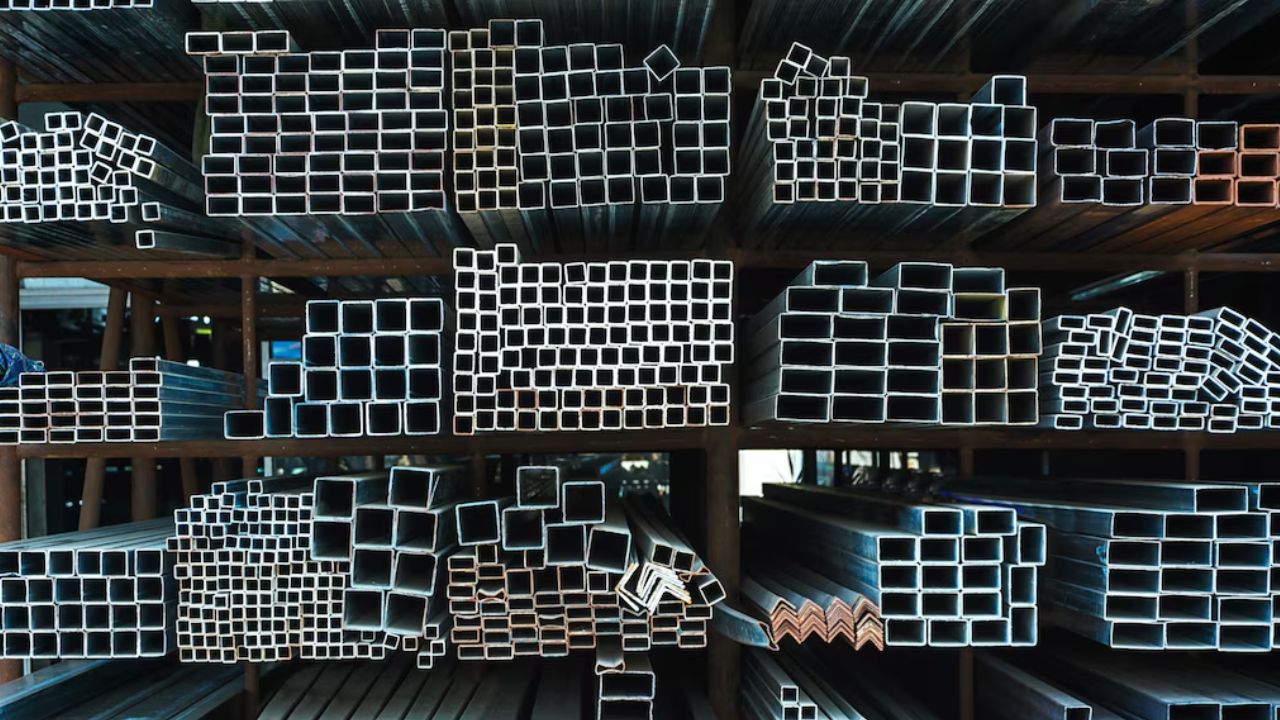

Modern industries rely heavily on steel pipes. Accurately measuring their weight is necessary because slight miscalculations can increase expenses and cause potential structural failures. Whether using manual methods or a Steel Pipe Weight calculator, accuracy is key for project success.

This article explores the formulas, elements that affect weight, and the usefulness of steel pipe weight calculators.

Importance of Steel Pipe Weight Calculation

Determining the precise weight of a steel pipe is crucial for multiple reasons:

Transportation & Handling

Steel pipes become logistically problematic due to their density. Accurate measurements or weight calculations help in many transportation projects such as planning lifts and can reduce the risk of any kind of structural harm, inaccurate handling, and unproductive materials usage.

Budgeting & Cost Estimation

Since steel pricing is frequently based on weight, precise calculations help businesses avoid overspending or underestimating material costs, leading to better financial planning.

Project Management & Logistics

From storage to installation and labor planning, every aspect of project execution depends on knowing the steel pipe’s weight. Accurate prediction can prevent unnecessary costs and unexpected events.

Key Factors Influencing Steel Pipe Weight

Several elements determine a steel pipe’s overall weight:

Outer Diameter (OD)

The outer diameter dictates the pipe’s overall size and material volume. Larger diameters generally contribute to increased weight.

Wall Thickness

Pipes with greater wall thickness contain more material per unit length, directly impacting their weight. This factor is crucial when applying the steel pipe weight formula in kg.

Pipe Length

Since weight is proportional to length, longer pipes naturally weigh more.

Steel Density

Steel’s density is equal to 7850 kg/m³. While variations exist between stainless steel and carbon steel compositions, this value remains the benchmark for most calculations.

Manual Steel Pipe Weight Calculation

To compute the weight of a steel pipe manually, apply the following formula:

Total Weight (kg) Formula:

- π = 3.14159

- OD = Outer Diameter

- Wall Thickness Outer Diameter and is measured in millimeters (mm)

- Length is measured in meters (m)

- 0.00785 is the density conversion factor for steel

This formula provides the total steel pipe weight in kilograms for any given length.

Weight Per Meter (kg/m) Formula:

The equation for weight per meter is:

Weight (kilogram/meter) = (π * (Outer Diameter (mm) - Wall Thickness (mm)) * Wall Thickness (mm) * 0.00785)

This version helps estimate weight distribution per unit length, assisting in material planning.

Benefits of Using a Steel Pipe Weight Calculator

The manual calculation might have errors and is time-consuming. In contrast, a steel pipe weight calculator helps in a quick and simple process with high accuracy.

Advantages of a Pipe Weight Calculator:

Quick Results: Provides quick calculations on one command without the need to apply formulas one by one.

User-Friendly: It is user-friendly as compared to doing manual calculations, it just needs basic requirements to get the weight such as you need to input the wall thickness, diameter and length, etc.

Improved Accuracy: It is free from human mistakes, providing more accuracy and reliability.

Minimizes human mistakes, ensuring more reliable estimations.

Unit Conversion: The most effective feature of online weight calculators is that they provide unit flexibility such as millimeters to inches, kilograms to lbs, etc.

Types of Pipe Weight Calculators:

Pipe Weight Calculator in KG/Meter: An Accurate Tool for Estimating Material

An essential instrument for performing exact calculations and guaranteeing efficiency in both application and procurement is a pipe weight calculator, which is measured in kilos per meter.

Important Factors in the Calculation of Steel Pipe Weight

A number of crucial elements affect the precision of steel pipe weight calculations, whether an empirical approach or a sophisticated digital computer is used:

Precision in Measurement: Reliable weight calculations depend on precise measurements of the exterior diameter and wall thickness. Significant differences in material estimates might result from even small variances.

Coatings & Linings: Protective finishes such as galvanizing or painting add extra weight—factor them into calculations.

Material Variability: While 7850 kg/m³ is the standard density, some steel grades have slight density fluctuations.

Expert Consultation: For large or critical projects, seek insights from structural engineers or steel suppliers to validate calculations.

Conclusion

Accurate steel pipe weight assessment is fundamental to project success, whether for budgeting, logistics, or structural integrity. Utilizing either a manual steel pipe weight formula in kg or an automated steel pipe weight calculator in kg/meter ensures precision, efficiency, and cost-effectiveness. By accounting for key variables like outer diameter, wall thickness, and length, professionals can optimize material usage and streamline project execution. For large-scale operations, leveraging a steel pipe weight calculator enhances accuracy and saves valuable time, facilitating smoother workflows and improved resource management.