Manufacturers depend on fluid control to produce high-quality ink, paints, and coatings for their industrial operations. PVA 2488 helps control rheology parameters in these mixtures. Companies use this high-grade polyvinyl alcohol material and its exceptional flow benefits to create industry-specific products that require accurate material handling. This article examines the impact of pva 2488 wholesale on viscosity control and flow improvement in industrial applications, particularly inks and coatings. Want to know every single fact? Just stick to this article and keep reading!

Understanding Rheological Control in Industrial Formulations

Studying how materials flow and change shape helps manufacturers produce better coatings and inks. Viscosity is a rheologic property that controls how well products apply and dry and determines their final quality. Rheological control helps inks and coatings flow evenly during application while keeping them practical for the needed duration.

Formulating coatings and inks requires developers to balance viscosity levels with necessary surface adhesion and environmental response attributes. Our PVA 2488 wholesale product gives customers better control over product flow to address their specific challenges. The product’s unique features help formulation experts keep viscosity and flow steady to avoid product separation and uneven distribution. Our products deliver consistent performance results within different usage scenarios.

PVA 2488: A High-Performance Rheology Modifier

PVA 2488 performs better as a rheology modifier because it adjusts viscosity effectively while keeping other material properties intact. The PVA variant 2488 dissolves well in water and integrates smoothly with aqueous systems without affecting other ingredients. The unique structure of PVA 2488 helps create better thickness and flow control for coating and printing materials.

When we use PVA 2488, it helps stabilise the physical properties of formulations while they age. The material keeps output steady while creating stable applications that work as expected.

Enhancing Ink Formulations with PVA 2488

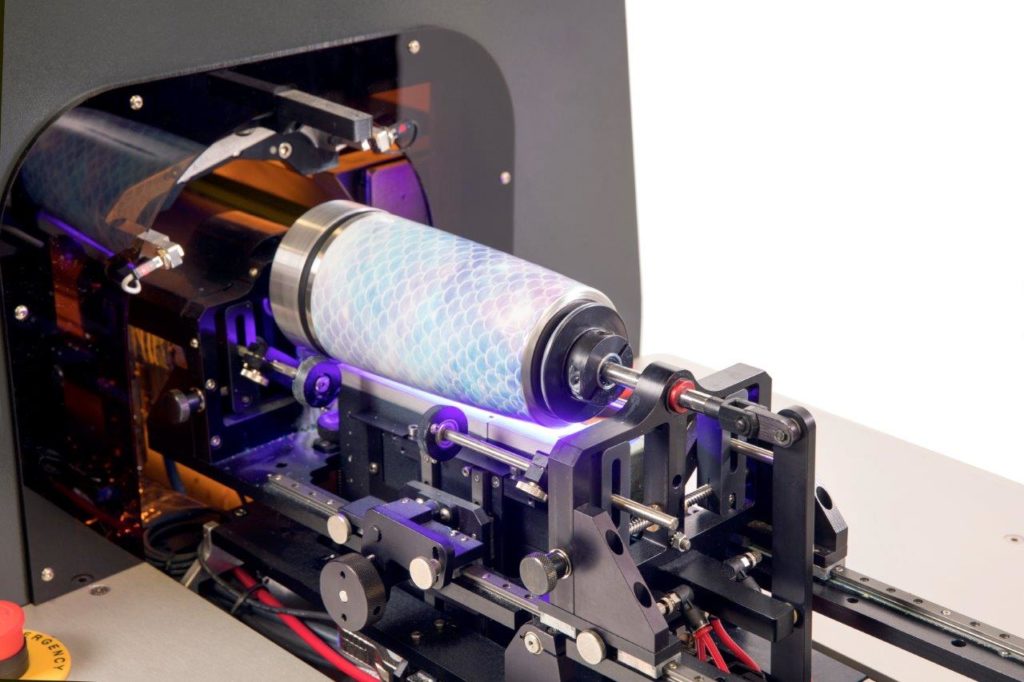

PVA 2488 enhances the performance of ink solutions during printing and spreading. It modifies the flow characteristics of ink to work reliably across all printing technologies. Ink control systems with PVA 2488 improve print jobs by stopping problems that hurt image quality and frustrate customers.

Adding PVA 2488 to ink enhances its ability to stick to multiple printing surfaces. The result is printed materials that remain usable longer despite regular use. The ink with PVA 2488 sticks to printing surfaces, including paper and textile materials, to create superior-quality prints.

Rheological Stability in Coatings: How PVA 2488 Adds Value

Coating formulations need precise flow control to stop liquids from spilling or pooling during application. When applied, PVA 2488 creates consistent surface coverage because it helps coatings flow evenly across different surfaces. This polymer thickening agent maintains clarity while improving viscosity in coatings that need a shiny, transparent effect. Automotive and furniture finishing uses this technique effectively.

PVA 2488 protects coatings from degradation throughout their useful life. Managing viscosity and flow keeps formulations from breaking down, which preserves their performance standards over time. A consistent base is necessary so coatings can deliver their protective and attractive performance throughout their life cycle.

Optimising Formulations for Industrial Efficiency

Formulations that use PVA 2488 save money because it is a versatile, cost-effective ingredient. It serves multiple functions by replacing thickening and stabilising agents for simple formulation preparation. Using PVA 2488 simplifies production methods, which saves money while making work run better. PVA 2488 speeds up manufacturing steps to produce products efficiently with less possibility of mistakes.

Formulations work better with PVA 2488, which helps produce less excess product during manufacturing. Using PVA 2488 enables formulators to reach better results with smaller amounts of raw materials, reducing production costs.

Sustainability and Eco-Friendly Benefits in Rheology Management

Businesses in today’s industries strongly focus on sustainability practices. PVA 2488 brings significant environmental advantages that support the current need for greener manufacturing operations. Our product breaks down naturally, allowing manufacturers to limit their environmental impact. PVA 2488 lowers production waste and energy needs, making it perfect for companies working toward sustainability targets.

The PVA 2488 product meets regulations for eco-friendly production with its biodegradability, low VOC, and non-toxic characteristics. It provides safer alternatives to existing thickeners and stabilisers containing dangerous elements.

Conclusion

PVA 2488 offers various perks as a rheology modifier in industrial formulations. Manufacturers prefer it because it assists them in managing product viscosity. Multiple industries use it because it provides cost savings while preserving resources and ensuring product quality remains consistent. The future development of ink and coating technologies will depend on PVA 2488’s essential function in enhancing product performance.