Application of PU Timing Belts in Flour Roller Mills and Food Processing

Efficiency, hygiene, and precision are necessary in the food processing industry. In particular, flour roller mills use mechanical processes to grind grains into high-quality flour. One of the elements that has ensured the smooth operation of these machines is Polyurethane (PU) timing belts. PU Timing Belts are known to be durable, precise, and low-maintenance, and are very useful in maintaining the same production and reducing downtime in food processing and flour roller mills.

What Are PU Timing Belts?

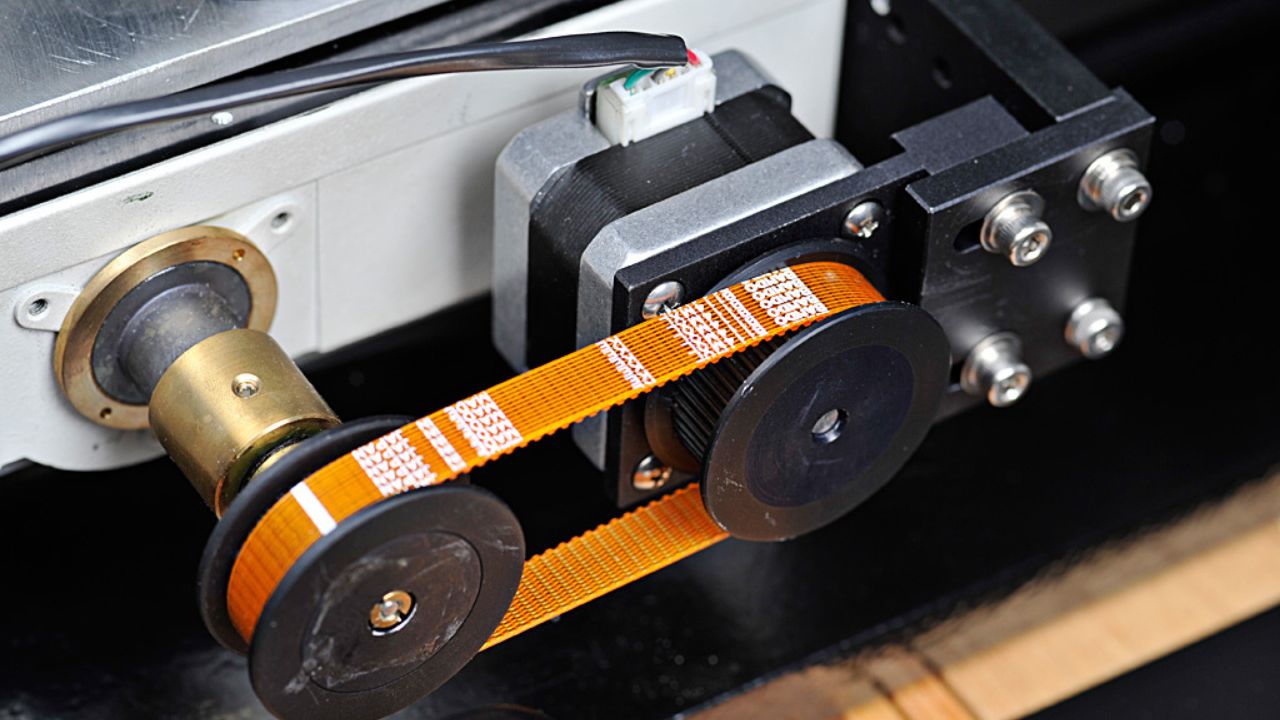

People in business use the Polyurethane timing belts, which are high-performance belts that are made of tough PU material, and they have fibers added to them, e.g., steel, Kevlar, or polyester. These belts have teeth that fit perfectly with the corresponding pulleys, with a precise and accurate synchronization between the driving and driven parts. In comparison to the regular V-belts, PU timing belts will not slip and hence offer a positive drive, which is important in processes that require timing and precision. This accuracy in flour roller mills ensures uniformity in the grinding and processing of grains, and this directly affects the quality of the end product, i.e., flour.

The Benefits of Using PU Timing Belts in Food Processing

There are several benefits of PU timing belts as compared to traditional rubber belts, and the product is recommended in the food industry. Among the greatest advantages is their durability. PU belts are resistant to wear, abrasion, and stretching, and this guarantees the service life even during continued service. This durability minimizes the rate of replacing belts and lowers the downtime of the flour roller mills and processing plants.

In addition, PU belts are also food safe and hygienic. Polyurethane is naturally resistant to oils, fats, and many other chemicals, which are very necessary in food processing plants. These belts could be of food-grade quality that would help the plants to meet the hygiene standards and reduce the possibility of contamination.

Necessary Parts of PU Belts

The teeth on the belt regulate rollers and other moving parts to create a uniform milling and uniform flour fineness. The precision also avoids damage to equipment that might be caused by a slip or a lack of alignment. Moreover, the PU timing belts are not as noisy as the metal chains or traditional rubber belts, and they provide a more comfortable and safer working environment for the operators of the plant.

PU belts could also resist the different temperatures and other mild chemicals, which are employed in food production. This ensures that they are compatible with equipment that needs cleaning regularly or one that does not perform well in changing circumstances without affecting its durability.

Flour Roller Mill Applications

PU timing belts are applied in various vital sections of the roller mills. In roller drives, these belts ensure that the rotation of grinding rollers is very precise, and keep the speed ratios required to mill uniformly. Timing belts are also used in strainer and separator systems to coordinate the movement of the equipment and make the separation of flour and bran, as well as other by-products, effective. PU belts are commonly used in conveyor systems to transfer grain and flour or other substances between processing operations and allow smooth and dependable material flow. In addition to these main applications, numerous auxiliary machines, such as feeders, bagging systems, and cleaning devices, require PU timing belts to operate correctly and provide the same performance.

Optimum Performance Maintenance

Although PU timing belts are very strong, they need to be well-maintained in order to give maximum life. Routine checks are used to determine the wear, cracks, or stretching before failure leads to unplanned downtime. It is also necessary to ensure the proper tension because the belts that are tightened incorrectly may slip or tear irregularly. Washing off the belts of excess flour and debris and correctly centring the pulley systems will help to increase the lifespan of the belt, as well as ensure that the wear on the belt is not uneven, prolonging the life of the belt.

Conclusion

Polyurethane timing belts have gained a lot of relevance in flour roller mills and food processing machinery. They are very durable, precise, and hygienic, making them best suited to the rough environment of the food industry. PU timing belts can be used to guarantee quality products, minimize downtimes, and improve overall operational efficiency due to proper synchronization of the rollers and auxiliary systems. In the case of manufacturers and plant operators that want to have quality PU timing belts that are food safe, reliable, and long-lasting, investing in quality PU timing belts will be not only an operational decision, but also an investment towards consistency, safety, and quality in food processing.